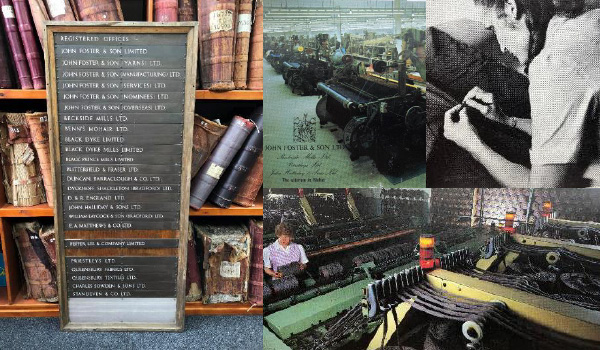

John Foster, a pioneer of the modern wool textile industry and founder of the world-renowned firm in Bradford, England which bears his name. Born in 1798 and at the age of 21, John Foster started his worsted business at a time when the factory system which was to revolutionise the textile industry, had not yet been established. By 1819, many inhabitants in the Bradford area had passed on skills in cloth production from generation to generation. It was these inherent local skills that became an asset of incalculable value to both John Foster and the British Textile industry. Taking advantage of a ready market for worsted cloth in Bradford and Halifax and with the start of an economic recovery, Mr John Foster set many handlooms to work in hundreds of cottages in and around Queensbury, Bradford. In time, John Foster became the largest employer of hand-loom labour in the district and acquired a considerable reputation for certain special fabrics. Fabrics known as ‘Lastings’ and ‘Damasks’ were a John Foster speciality. ‘Lastings’ as their name implies were textiles of very strong description, hardy, stout and sturdy, like the people who were engaged in producing them! In the years to come, John Foster became one of the world’s largest makers of worsted cloth.

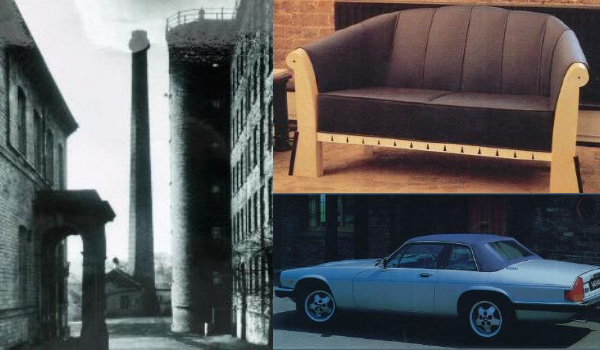

Under Mr Foster’s far-seeing enterprise and capable guidance, the business continued to expand and in 1832 he took over a large factory in Great Horton. Three years later in 1835, Mr Foster erected a mill in Black Dyke, Queensbury, on the site of a family farmstead. This mill became known as ‘Black Dyke Mills’, and was the foundation upon which John Foster’s immense business was built.

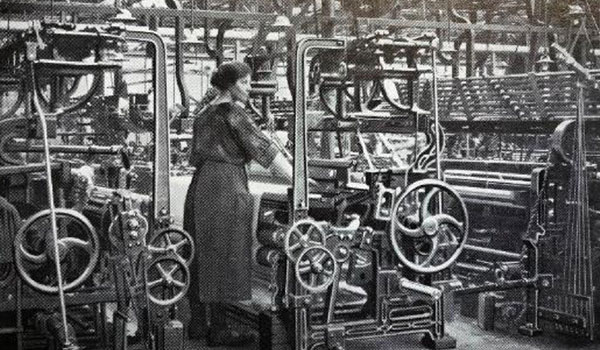

John Fosters road to success encountered the industrial revolution, a time of significant change. In 1836 a difficult period began in Black Dyke Mills as continued investment in new machines brought the transition from hand-loom to power-loom. Gas works were erected to supply the mill and village, and enlarged several times since to meet the increased power requirements.

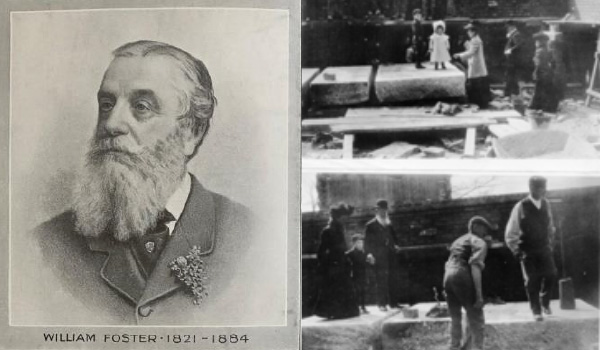

The direction of affairs passes from Father to son, William Foster becoming a full partner in the business and maintaining traditions of the firm through the next generation. William Foster was the eldest son of John Foster and was admitted into the firm as a partner in 1842. Other sons of the founder were also admitted into partnership in later years. The family connection was maintained until circa 1995. Black Dyke Mills had become a significant landmark and force in the global textile industry. William Foster is pictured with family members and mill workers overseeing building development and extension works.

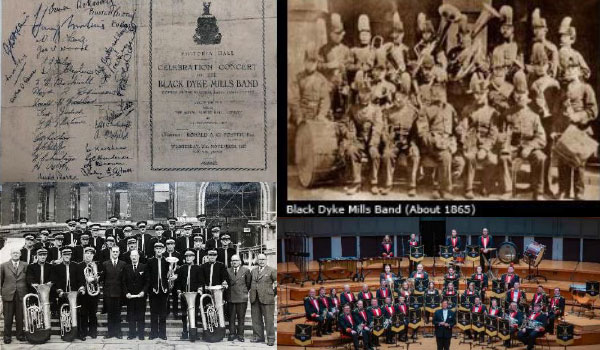

John Foster, a French Horn player, established the Black Dyke Mill Band in 1855 along with other musicians from a band formerly known as Queenshead Band. Many members of the band were originally workers at Black Dyke Mills and the band was outfitted in uniforms made from the mill’s own cloth. Today the band is one of the oldest and best-known brass bands in the world, winning many prizes and competitions over the years. The band has made over 350 recordings, including recordings for TV & Film, recorded with the Beatles and pop acts Tori Amos, Peter Gabriel and The Beautiful South, as well as working with Sir Paul McCartney to release a number of singles.

Over the next 30 years…

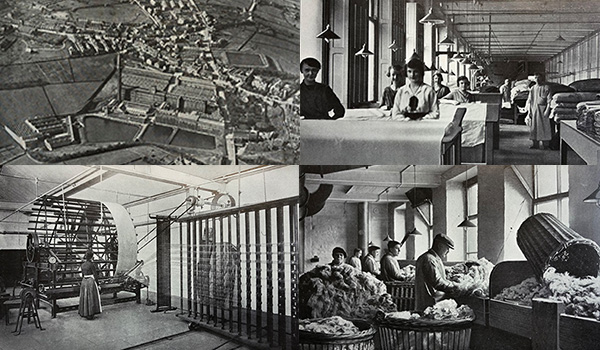

New Powerhouse to produce the immense amount of energy demanded by the mill.Development of subsidiary services including mechanics, joiners, plumbers, basket makers, cobblers, a fully equipped fire brigade, etc., makes the whole concern ‘self-contained’ and practically independent of outside aid. Thus enabling the mill community to proceed with clock-like manufacturing regularity and efficiency.

Total floor area of the mills exceed 15 acres and houses 500 power looms.

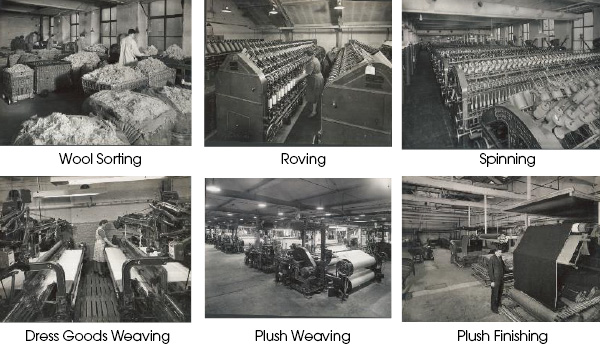

Every process of fabric production is integrated into the mill, from raw material sorting through to weaving, dying and finishing.

A hostel with 231 beds plus other facilities is built to provide accommodation for female skilled mill workers from distant locations.

By 1923, Black Dyke Mills has grown extensively and has its own water supply in the form of reservoirs.

Fibres being used include Cotton, Alpaca, Mohair, Wool & Silk.

John Fosters Portfolio is now extensive, with an almost endless variety of yarns and fabrics to include Mohair Brilliantines, alpaca linings, mohair velvets, silk seals, Sicilians, Grenadas, Botany dress goods, etc.

Demand is increasing for hosiery goods and soft-handling fabrics.

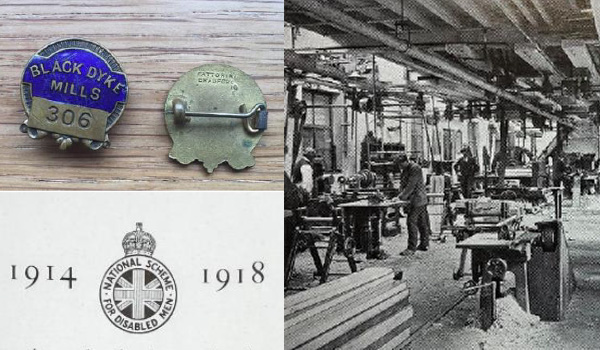

The 1st world war breaks out and the whole of the textile machinery was soon engaged in providing materials for uniforms and knitted goods for the Allied Armies. Textile production was not the only area of the John Foster business influenced by war activities. The well-equipped engineering and wood-working departments were used by the Ministry of Munitions and took a very creditable share in the production of munitions that helped bring the war to a victorious end. Directors of John Foster guarantee to keep open the places of all male workers enlisted to join the army, participating in the National scheme for disabled ex-servicemen. The firm employed 167 ex-servicemen, of whom 38 were partially disabled. During world war one, military exception badges were issued to some workers of Black Dyke Mills who had ‘reserved occupations’ such as mill workers or farmers and were exempt from military service.

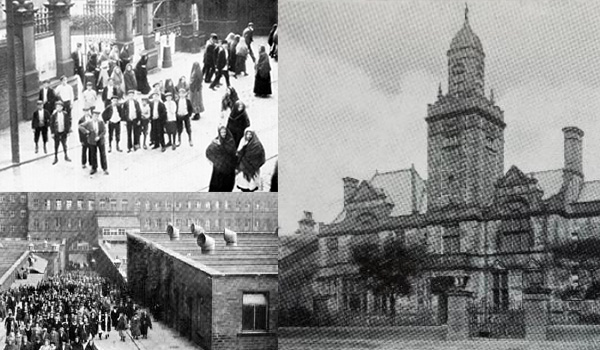

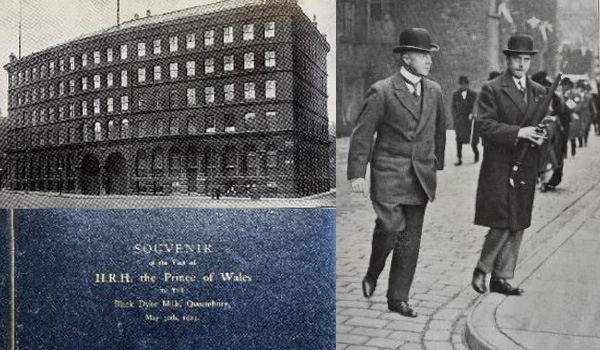

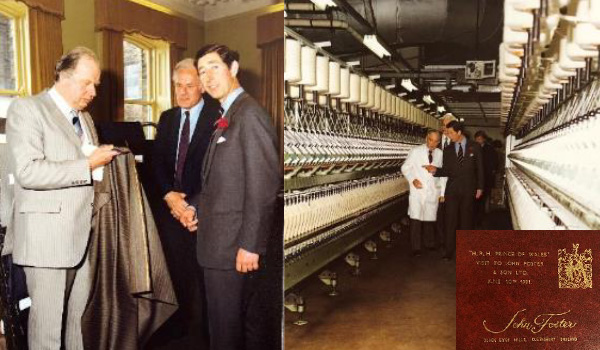

Black Dyke Mills welcome a visit from HRH The Prince of Wales on 30th May, as he visits a number of Yorkshire towns. The purpose of his visits was to gain first-hand knowledge of conditions in the textile, steel and other industries for which the county is famous. John Foster are now a significant employer in the Bradford area, employing 1,400 workers across the mill and offices. John Fosters Bradford Office is pictured above.

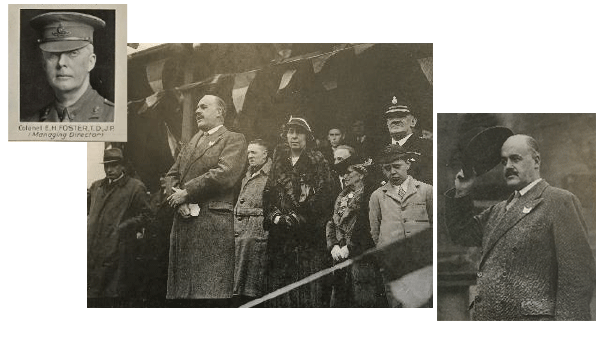

John Foster are very much still in their peak and have an impressive portfolio, welcoming distinguished international visitors to the mill. The Chinese ex-president being one who paid a visit to the famous Black Dyke Mills in 1924. At this time Colonel Edward Hornby Foster (Grandson of John Foster) is Managing Director of the firm.

John Foster built a loyal workforce at Black Dyke Mills and in 1937 proudly showed off to the local newspaper 21 employee’s who had all worked for the company for over 50 years. They have worked a total of 1,100 years, their ages total over 1,420 years. Between them in the last half-century, they have drawn more than 55,000 weekly wage packets. They nearly all started working as half-timers at the age of ten and regarded ‘Foster’s’ as a 2nd home. They have never been ‘pennied’ – an old custom of knocking off a penny for unpunctuality.

During the years of the 2nd world war, Colonel E.H.Foster, aged 70 died in 1940, he was Managing Director of John Foster at the time and grandson of the founder. In 1943 Ronald Foster (chairman of John Foster), is seen here getting involved in ‘Wings for Victory’ week which was held across the country to raise money for Spitfires and Bombers.

£1million invested in new equipment for Black Dyke Mills, to increase production and efficiency and improve quality even further. Record Sales and Profits are recorded with exports accounting for 60% of sales. After the UK, Japan and the Far East is the biggest most significant export market for John Foster products.

During the 1970s-1980s, rapid expansion into other non-core textile sectors such as automotive and other non-apparel sectors pushed John Foster to its limits. Despite being at the height of activity in the mill, John Foster went into administration and decisions were made to downsize and eventually move premises. Black Dyke Mill and other mill assets were sold off. In order to maintain the world-renowned John Foster name and continuity of textiles woven in Yorkshire, the business continued with the investment of new partners dedicated to manufacturing wool products for apparel and maintaining the skills of the industry.

In 2009 John Foster business ownership transfers to SIL Holdings Ltd, is given a new lease of life and moves to new premises in Bradford, Stanley Mills. SIL Holdings is a British group of vertically integrated textile companies encompassing all elements of textile production from luxury fibre – to – exquisite fabric.

John Foster cloth features on a Royal Mail special edition 1st class stamp

Royal Mail featured British designer Paul Smith on its 1st class stamp. The cloth is John Foster iconic 60% adult mohair and 40% wool in a vibrant blue.

John Foster wins No.1 Fabric award from Saks 5th Avenue.

Saks 5th avenue identifies British Mill John Foster as a Top Men’s Fabric producer of fine fabrics for suitings. John Foster’s 90% Super 150’s wool & 10% cashmere worsted spun cloth in a navy stripe is their fabric of choice.

David Gallimore, the Managing Director of John Foster meets with HRH The Prince of Wales, patron of The Campaign for Wool.

HRH Princess Ann visits the mill to celebrate the company’s £1.2m investment in five new Dornier weaving machines. The investment allowing John Foster to keep apace with growth in demand, maintain their reputation of top-class cloth and continue into the future with a strong focus on innovation and quality.

Alexander McQueen celebrates the Yorkshire textile industry by using John Foster’s Oxbridge Flannel in their collection.

In March 2019 Alexander McQueen presented their Autumn/ Winter 2019 collection at Paris Fashion Week; opening the show with a garment made from our cloth ‘Oxbridge Flannel’.

Masterminded by Creative Director Sarah Burton this collection paid homage to the Yorkshire textile industry and drew inspiration from her childhood growing up in Macclesfield, Yorkshire.

“I went home for this collection, back to where I grew up in the North of England, surrounded by mill towns and wild countryside. I took my team to those mills, to a landscape that I remember from my childhood. The heart of the collection is inspired by the bolts of cloth we saw woven both by man and machine,” she said backstage at the show.

Burton and her team visited a number of Yorkshire textile brands including John Foster at Stanley Mills, Bradford while researching for the collection.

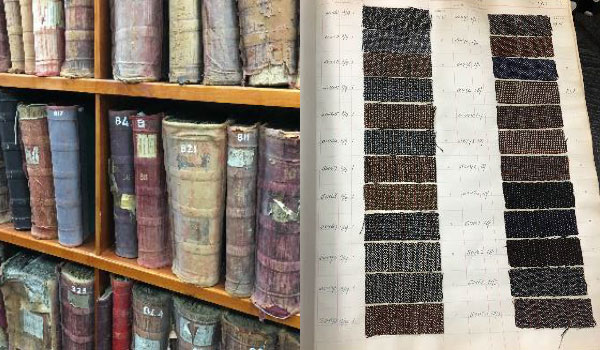

David Gallimore, Sales Manager at John Foster said: “It was a real honour and a privilege to have the McQueen team visit the mill and study our archives.

“It was amazing that Sarah Burton also visited the us,” he added.

The McQueen team delved into the history of the mills to drive the direction of the collection.

“We have a very strong history and some extensive archives that allowed the McQueen team to delve back into our 200 year past,” Gallimore said.

Burton was clearly inspired by her time at Stanley Mills, and other textile mills across Yorkshire, and the collection and show reflected that. The venue was styled industrially and guests sat on huge bolts of fabric.

John Foster’s wool cloth, woven in the very mill Burton and her team visited, played an important part in the collection. The show opened with a model wearing a structured pantsuit with an asymmetric train made from John Foster’s signature ‘Oxbridge Flannel’ cloth. In a further nod to the origin of the cloth, and an interesting design touch, the selvedge was left visible.

Gallimore said: “We are really excited that Alexander McQueen have chosen to use John Foster cloth. Their selection is from our new collection Oxbridge Flannel, which is being showcased using the woven selvedge as part of the garment.

“The cloth was selected due to its vintage character, as well as the weight and handle achieved by the art of a double mill finish,” added Gallimore.

Burton’s collection was a celebration of Yorkshire and the cloth made here at the heart of the textile industry.

“To have Alexander McQueen working closely with a Yorkshire mill has allowed us to showcase how good we are on the international stage,” says Gallimore, “We are extremely proud to be part of this partnership.”